When the oil gets into the urine, it spreads cursorily over the open of the body of water, and the volume of contamination depends on the relative density and typography of the oil. The results can be black as anoint shininess on water has a meaning impact on ocean animals and humans. Any petroleum spill not only affects the current marine environment but besides impacts the marine species and coastal constituent substrate .

The immediate effects of toxic and smothering vegetable oil waste may be mass deathrate and contaminant of fishes and other food species, but long-run ecological impacts may be worse .

petroleum waste poisons the sensitive marine and coastal organic substrate, interrupting the food chain on which fish and ocean creatures depend, and on which, their generative achiever is based. commercial fishing enterprises may besides be affected permanently.

Related Read: 11 major Oil Spills Of The Maritime World

The occurrence of oil spillway incidents at sea has drastically reduced in late years ; however, it can not be permanently eliminated .

The confirm objective of MARPOL Annex 1, which entered into force on 2nd October 1983, is to protect the marine environment through the dispatch elimination of befoulment by anoint and other damaging elements and to lessen the chances of accidental drop of any such elements .

Related Read: MARPOL ANNEX 4 Explained

Defining Oil Spill At Sea

The term “ Oil ” can be defined as a gluey fluid containing petroleum which can be in the form of unrefined petroleum, heavy fuel oil, sludge, oil defy and refine products like MGO ( early than those petrochemicals which are subjected to the provisions of annex2 of the present conventionality ), etc .

As per this Annex, all ballast body of water and tank washing remainder originating from the lave of cargo tanks in the oil tanker ships are besides included .

MARPOL Annex 1 covers all the fluids which contain oil and can be discharged overboard at sea. even the OWS treated dismissal water system is besides a share of this annex. Under the MARPOL Annex 1, the take after equipment should be in beneficial working circumstance, adequately calibrated, maintained and amply functional with allow spares present onboard at all times-

All ships:

1. oil filtering equipment.

2. 15 PPM alarm arrangements.

3. Standard free connection .

Related Read: What is International Shore Connection ?

Tanker specific:

1. Oil/ water system interface detector

2. Crude petroleum washing organization, if fitted

3. Oil fire monitoring and command

4. Cargo and ballast pump, piping and discharge arrangements.

5. Engine room/ bilge holding tank to slop tank pump and shriek musical arrangement .

Related Read: A Detailed Explanation on How to Operate a Ship ’ s Ballast System

Special areas under MARPOL Annex 1:

1. The Mediterranean Sea.

2. baltic Sea.

3. The Black Sea.

4. The Red Sea.

5. “ Gulfs ” area.

6. The Gulf of Aden.

7. south-polar ocean.

8. union west european waters.

9. Oman area of the Arabian Sea.

10. southerly south african waters .

Related Read: FAQs : Sulphur Limits In Emission Control Areas

Control of Discharge of Oil under MARPOL Annex 1 Regulation 4

Under this rule, any discharge of anoint or oily mix generating from the ship ’ s engine room or cargo spaces of oil tanker transport is prohibited, except when they fulfil the surveil stated criteria –

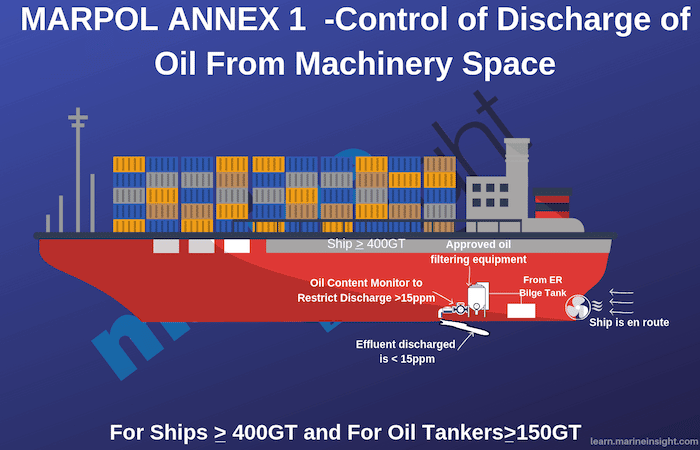

All embark ’ sulfur of 400GT ( other than oil tankers ) and above sailing outside the special areas, the empty from the machinery spaces, is permitted if :

1. The ship is en route

2 merely treated oil-water mix which is processed through an approve oil filtering equipment fulfilling the prerequisite stated in regulation 14 is used to discharge the treat effluent mix

3 The petroleum PPM in the treat effluent without dilution must not exceed 15 parts per million

4 The greasy concoction being treated in the oil percolate equipment is only taken from the locomotive room and not generating from cargo holds

5 The oily mix is not mix with fuel tanks or cargo tanks vegetable oil residues

4. The ship is more than 12 nautical miles from the nearest land

Discharges in special areas

For this ships of 400GT and above ( other than oil tankers ), any free of petroleum or greasy mixture out at ocean is forbid, except when all the following requirements are fulfilled :

1 the embark is proceeding en route ;

2. only treated oil-water mixture which is processed through an approved petroleum filtering equipment fulfilling the condition stated in regulation 14 is used to discharge the treat effluent mix

3 The oil PPM in the tempered effluent without dilution must not exceed 15 parts per million

4. In the extra area of the Antarctic, any acquit into the sea of oil. Oil effluent or buttery mixtures from the embark shall be prohibited .

Related Read: 7 Ways For Ships To Meet MARPOL NOx Tier III Regulation

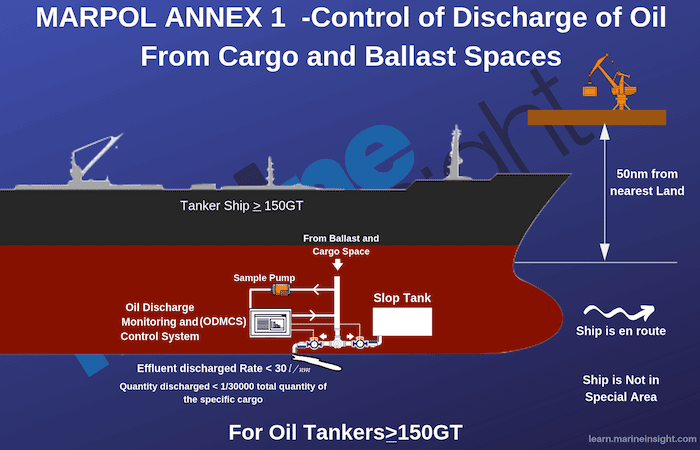

discharge from the Cargo Area of an oil tanker ( which includes cargo tanks, pump rooms, machinery space, bilges mixed with cargo anoint remainder, etc. ) –

- The tanker ship is not inside a Special Area;

- The tanker ship should be more than 50 nautical miles from the closest proximal land;

- The tanker ship is moving en route;

- The instantaneous rate of discharge of oil content does not exceed 30 litres per nautical mile

- The total quantity of oil discharged into the sea does not exceed for existing tankers (delivered on or before 31 December 1979 ) 1/15000 of the total amount of the particular cargo of which the residue formed a part, and for new tankers (delivered after 31 December 1979 ) 1/30000 of the total quantity of the specific cargo of which the residue formed a part;

- The tanker has in operational oil discharge monitoring and control system and a slop tank arrangement.

Discharge In Special Areas From Oil Tankers

Any greasy assortment or oil effluent dismissal from the cargo area of an vegetable oil oil tanker into the sea which comes under particular area shall be prohibited .

The prerequisites of this regulation shall not affect the fire of uninfected or segregated ballast tank .

In deference of the particular area of Antarctica, any discharge into the sea of greasy or mixtures from any ships shall be prohibited .

Related Read: Understanding Design Of Oil Tanker Ships

Survey under Marpol Annex 1

Every ship with 400GT and above and all tanker ships of 150GT and above must be subjected to following surveys :

1. Initial Survey: This view is performed before the ship is set in service. In this surveil all equipment, machinery, systems, fittings etc. are inspected which are covered under Annex 1 .

2. Annual Survey: The Annual surveil is performed every class taking a buffer of 3 months prior and after the anniversary date of the IOPP security issued .

3. Intermediate Survey: An average survey takes invest in a buffer of 3 months before or after the second-anniversary date or within 3 months before or after the third anniversary date of the Certificate replacing one of the annual surveys .

4. Renewal Survey: The Renewal review is done on or before 5 class period of the certificate termination date and in this survey as detail inspection of all equipment, material, machinery, fitting etc. which comes under Annex 1 are done.

5. Additional Survey: If there is significant repair and renewals are done on any of the machinery, system, fittings which comes under MARPOL Annex 1, an extra review is performed which can be general or overtone, depending upon the conditions .

6. Condition Assessment Scheme: The CAS is done to confirm that the geomorphologic persuasiveness oil tankers with the single hull are acceptable under the periodical surveys as indicated in the Statement of Compliance. The First CAS view is normally done in parallel to the inaugural average or renewal survey after 5 April 2005 or once the ship completes 15 years of age, whichever occur late .

Certificates, plans, and paperwork under MARPOL Annex 1:

International Oil Pollution Prevention Certificate (IOPP)

International Oil Pollution Prevention security is issued towards the initial or reclamation surveil which states that the ship equipment, system, fittings, machinery, etc. coming under MARPOL Annex 1 is compliant with the regulation. The robustness of this certificate should not be more than 5 years. The administration may decide to issue the security for a period of fewer than 5 years, depending upon several conditions .

If the certificate is on the scepter of run out, and embark is even out at sea engaged in a ocean trip, the government may extend the certificate validity so that ship can complete the voyage and come to a interface where the view can be done for renewing the certificate, however, the extension menstruation should not be more than 3 months .

The Validity the Certificate may expire in the take after conditions :

1. relevant surveys not carried out under a assign period as stated in the Annex.

2. If the second is not done as per the prerequisite of this Annex

3. If there is a change of masthead for the ship to another flag state .

Oil Record Book

anoint Record books are the authoritative text file which needs to be carried onboard ship under MARPOL Annex 1 on vessels of 400 crude tonnage and above, other than oil tanker, and vegetable oil oil tanker ship of 150GT and above .

The ORB part 1 is provided in all ships, other than vegetable oil tanker, of 400GT and anoint tanker ships of 150GT and above must be provided with Oil Record Book Part 1 and Part II ( for cargo/ballast operations ) .

The ORBs contains the following necessary information :

- Name and IMO Number of the ship

- Gross Tonnage of the ship

- Owner’s Details

- Official Number

- Period of usage

Related Read: The Most important Engine Room Documents a ship Can not Sail Without

ORB Part 1

vegetable oil Record Book Part 1 must be carried by All Ships and it should contain the following records :

- All the operations involving oil and oily mixtures

- Dates, geographical position, quantity, tank identification, and duration of operation entered

- Ballasting and cleaning of fuel oil tanks

– Discharge of dirty ballast or cleaning water from oil fuel tanks

– Disposal of oil residues (sludge)

– Non-automatic discharge overboard or disposal otherwise, of bilge water accumulated in machinery spaces - Automatic discharge overboard or disposal otherwise, of bilge water, collected in machinery spaces (e.g. transfer of bilge water to slop tank) (Identify tank)

- Conditions of ODM and Control System

- Accidental or other exceptional discharge of oil

- Bunkering of fuel or bulk of LO

- Additional operational procedures and general remarks

- Port State Authority may take copies of entries, and if so requested, the master is required to state that it is a true copy.

- ORB retained onboard for 3 years after the date of last entry.

Oil Record Book ( Part II), For Oil Tanker

In addition to ORB Part 1, the vegetable oil oil tanker ship of 150GT and above needs to additionally carry ORB separate II which records the oil-related activities from cargo and ballast spaces. It should contain the following records :

- Loading and unloading of oil cargo.

- Internal transfer of oil cargo during the voyage.

- Cleaning of cargo tanks.

- Crude Oil Washing(COW System only)

- Ballasting of cargo tanks

- Ballasting of Segregated Clean Ballast Tanks. (CBT Tanker only)

- Discharge of dirty ballast

- Discharge of clean ballast from the cargo tanks

- Discharge of ballast from Segregated CBTs (CBT Tankers only)

- Discharge of water from the slop tanks into the sea

- Condition of ODM and ControlSystem

- Accidental or other exceptional discharge of oil

- Additional operational procedures and general remarks

- Loading of ballast water. (Tankers engaged in specific trades)

- Location of ballast water within the ship

- Ballast water discharged to reception facilities

Related Read: 20 Hazards On Oil Tanker Ship Every Seafarer Must Know

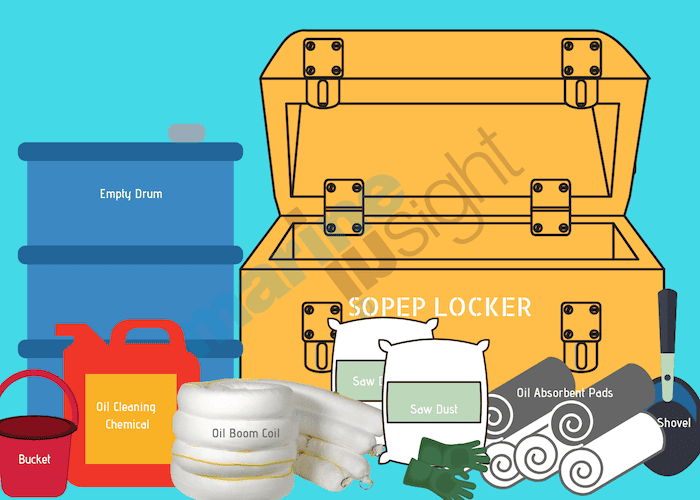

SOPEP – Shipboard oil pollution emergency plan

SOPEP is a full of life prevention plan which should be available onboard all ships of 400GT and above and on all anoint tankers of 150GT and above. The dispatch details of SOPEP are provided hera .

In addition to SOPEP, all oil tankers with 5,000 tons deadweight or more must have quick access to coast established cybernate damage constancy and residual structural intensity calculation programs .

Other essential requirements of MARPOL ANNEX 1

Fuel Oil Tank Protection:

All ships which are delivered after 1 August 2010, having a fuel petroleum capacity of 600m3 and more must comply with the play along regulations :

– Individual fuel petroleum tank should not have a capacity of more than 2500m3

– Those ships which have a fuel cooler capacity more than 600m3 but less than 5000m3, the fuel oil tank localization should be inboard of the shape wrinkle of slope blast plate, not less than watt described by the follow formula -w= 0.4+2.4X C/20000. ( the minimum value of west = 1.0m )

– Ships having entire fuel oil tank capacitance of 5000m3 and above, the fuel oil tank location should be inboard of the cast trace of side shell plating, not less than tungsten described by the follow convention – w = 0.5+C/20000 or w= 2.0 thousand whichever is lesser ( the minimal value of watt = 1.0m )

here C is total fuel oil volume .

Pump Room Protection:

The pump room, which is an substantive region of an oil tanker ship, is located at the buttocks partially of the vessel. It is provided with a double bottom, and it should be such that the distance between the bottom of the pump room and ship ’ mho baseline ( indicated as L ), when measured vertical, should not be less than L = B/15 or 2m whichever is lesser.

here B is the width of the transport .

Equipment under MARPOL Annex 1:

This is the equipment specific to the marine industry which is used to separate the petroleum from water system. It merely allows effluent of less than 15ppm to get discharged out at ocean. Read more about OWS here .

unblock eBOOK – A Guide to A Guide to Effective & Efficient Operating Oily Water Operation of Separator on Ships

ODMCS

This system is used on oil tanker ship to discharged effluent generated from cargo and ballast tanks. This is not a filtration unit of measurement, and it only monitors the subject and allows it to go overboard only when the ppm content is satisfactory. Read more about ODMCS hera .

Other Pollution Prevention Equipment and tools:

The SOPEP cabinet of the ship contains different pollution prevention tools, chemicals, and equipment which can be used for onboard oil befoulment to restrict the oil from going out at sea and besides for oil spill pollution to prevent diffuse of it .

Crew’s duty on the ship about MARPOL Annex 1:

The ship ’ randomness crowd plays the most vital function in implementing the MARPOL Annex 1 on ships. Following are the duties of the embark ’ s crew to keep check of this Annex :

– Maintain OWS, ODMCS and other MARPOL Annex 1 equipment in dependable running conditions

– Handle all oil transfer ( inner and external ) carefully to prevent any anoint spill

– Bunkering operation to be carried out after accomplished preparation

– All the records of the petroleum transfer, sludge, bilge, cooler wash, etc. to be maintained in the allow log books and oil record books

– Master should carry out regular pollution prevention education and drills onboard

– Every crew must be familiarised with the SOPEP footlocker and early contamination prevention equipment onboard ships

– The Ship ’ s officeholder must know how to fill the Appropriate anoint commemorate books

– The passkey and chief engineer must check the entries for there accuracy and countersign the ORBs

– The gang must try all the means to restrict any petroleum going overboard. If the ship is involved in an accident, the transport ’ sulfur crowd must try to minimize the oil stream out to the ocean if the transport is calm dependable to sail.

– Any accidental vegetable oil spill must immediately be informed to the shore administration

Related Read: Actions to be Taken by the Master and Parties Involved in Case of Collision of Ships in amerind Waters

Role of Port State Control (PSC)

The main aim of any Port state control inspection is to find a lack in the vessel when they visit their port so that it can be rectified and the transport is safe when out at sea .

Under MARPOL Annex 1, following equipment, systems and logs are normally checked by the PSC examiner :

– The oil record ledger is checked for different entries

– The sounding log reserve is checked, and PSC examiner may ask to take actual sounding for cross-checking the quantities

– The engine room bilges for oil contentedness

– Leakages in the machinery which may contribute to buttery bilges

– The discharge pipe of the OWS ( before the overboard valve ) can be opened and checked for buttery layer, which indicates the OWS is not performing as per the standards

– The operational log of the vegetable oil capacity meter

– The robustness of the IOPP certificate

– The seals on the OWS discharge valve and ODMCS discharge valve

– The PSC examiner may randomly pick a crew and ask questions on oil spill drill or SOPEP locker location to check the practical cognition and familiarization of the gang regarding his/her embark

Related Read: 40 Ship Certificates and Documents that are Checked in a Port State Control ( PSC ) Survey

Read more: What is the Maritime Industry?

MAPROL Annex 1 is one of the first Annexes which came into effect to prevent Marine Pollution. It besides includes port reception facilities and their requirements so that ship can dispose of sludge and bilges which can not be treated and discharged overboard .

Disclaimer: The authors ’ views expressed in this article do not necessarily reflect the views of Marine Insight. Data and charts, if used, in the article have been sourced from available information and have not been authenticated by any statutory assurance. The author and Marine Insight do not claim it to be accurate nor accept any duty for the same. The views constitute lone the opinions and do not constitute any guidelines or recommendation on any class of carry through to be followed by the reviewer .

The article or images cannot be reproduced, copied, shared or used in any form without the permission of the author and Marine Insight.